Back to top

Advanced Insulation and Dielectric Strength

With insulation classes A, F, and H, these transformers provide robust protection against thermal and electrical stresses. Dielectric strength up to 28 kV ensures safe operation, even in challenging environments, contributing to enhanced reliability and a longer operational lifespan.

Versatile Mounting and Enclosure Options

Choose between skid or wheel-mounted models to best suit your site requirements. Enclosure protection levels of IP23 or IP44 guard against dust and water, ensuring the transformers integrity whether installed indoors or outdoors in varied climates.

High-Efficiency Design and Performance

Achieving 98.5% efficiency, our transformers minimize energy losses and reduce long-term operational costs. Their low no-load and load loss performance complies with IS and IEC benchmarks, supporting sustainable utility and industrial infrastructures.

We Are Mainly Deals In Uttarpardesh, Rajastaha, Uttaranchal, Punjab, Uttarakhand

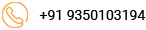

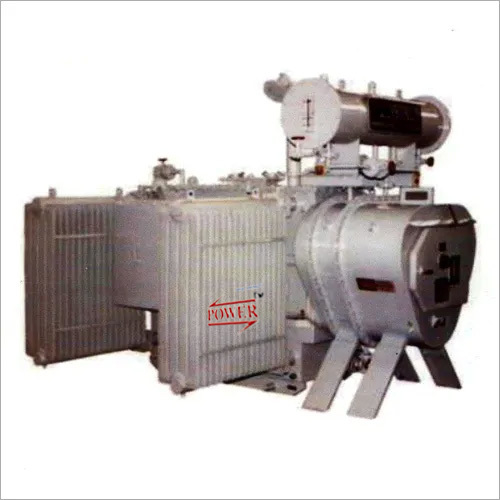

Electrical Power Transformer

Product Details:

- Standard IS 2026 / IEC 60076

- Operating Temperature -25C to 55C

- Rated Voltage 11 kV / 22 kV / 33 kV

- Dimension (L*W*H) Customized as per capacity

- Cooling Type ONAN (Oil Natural Air Natural)

- Capacity Up to 2500 kVA

- High Voltage 11 kV 33 kV

- Click to View more

X

Electrical Power Transformer Price And Quantity

Electrical Power Transformer Product Specifications

- Low, as per IS standards

- Customized as per capacity

- ONAN (Oil Natural Air Natural)

- 11 kV / 22 kV / 33 kV

- -25C to 55C

- 98.5%

- 415 V 690 V

- High Grade Copper

- Varies by rating (approx. 1500-4500 kg)

- Copper and Silicon Steel Core

- Up to 2500 kVA

- Customized as per requirement

- Toroidal

- On Load Tap Changer (optional)

- Three Phase

- Double Winding

- Up to 2500 kVA

- 11 kV 33 kV

- Power Distribution and Transmission

- 50 / 60 Hz

- IS 2026 / IEC 60076

- Electrical Power Transformer

Product Description

Electrical Power Transformer is designed to control the voltage/current applied to various electrical equipments & machines. It has the capability to change the level of voltage from one stage to another. Made of chosen grade of electrical parts & components, the Electrical Power Transformer features sturdy construction, great energy efficiency and longer functional life.

Advanced Insulation and Dielectric Strength

With insulation classes A, F, and H, these transformers provide robust protection against thermal and electrical stresses. Dielectric strength up to 28 kV ensures safe operation, even in challenging environments, contributing to enhanced reliability and a longer operational lifespan.

Versatile Mounting and Enclosure Options

Choose between skid or wheel-mounted models to best suit your site requirements. Enclosure protection levels of IP23 or IP44 guard against dust and water, ensuring the transformers integrity whether installed indoors or outdoors in varied climates.

High-Efficiency Design and Performance

Achieving 98.5% efficiency, our transformers minimize energy losses and reduce long-term operational costs. Their low no-load and load loss performance complies with IS and IEC benchmarks, supporting sustainable utility and industrial infrastructures.

FAQs of Electrical Power Transformer:

Q: How is the electrical power transformer installed and where can it be mounted?

A: The transformer is offered in both skid and wheel-mounted configurations, providing flexibility for indoor or outdoor installation. It comes with enclosure protection (IP23/IP44) and can be mounted as per site-specific requirements, ensuring safe and stable placement in power distribution or transmission settings.Q: What are the main benefits of using a transformer with insulation class A, F, or H?

A: Insulation classes A, F, and H define the transformers maximum operating temperature limits. Higher insulation classes, such as F and H, support hotter operating environments, improving safety, reliability, and lifespan, especially in regions with elevated ambient temperatures or high electrical loads.Q: When should the on load tap changer (OLTC) option be selected for this transformer?

A: An OLTC should be chosen if voltage regulation under varying load conditions is required, such as in distribution networks with fluctuating demand. The OLTC provides +5% to -15% voltage adjustment in 2.5% steps, ensuring consistent performance and voltage stability as operational needs change.Q: What materials are used in the construction of the transformer core and windings?

A: The core is fabricated from high-quality Cold Rolled Grain Oriented (CRGO) silicon steel, and the windings utilize high-grade copper. This combination ensures minimal losses, high efficiency, and structural durability throughout the transformers service life.Q: How does the transformer ensure operational safety and compliance with standards?

A: Each unit undergoes short circuit withstand and dielectric strength tests according to IS/IEC standards. Features like oil-immersed cooling (ONAN), solid bushing choices (porcelain/polymer), and robust enclosure options help maintain compliance and enhance safety for a wide operating temperature range.Q: What range of capacities and voltages are available for this transformer?

A: Transformers are available with rated high voltages of 11 kV, 22 kV, or 33 kV and low voltages ranging from 415 V to 690 V. Their capacity reaches up to 2500 kVA, with dimensions and outputs fully customizable to specific project needs.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Transformers' category

We Are Mainly Deals In Uttarpardesh, Rajastaha, Uttaranchal, Punjab, Uttarakhand

|

ARORA ELECTRICALS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry Send SMS

Send SMS