Back to top

Custom-Built for Your Furnace Needs

These electrical furnace transformers can be fully customized in terms of capacity, dimensions, low voltage requirements, and coil material. Whether for steel making, foundries, or specialty furnaces, our engineers design solutions that fit your exact operational parameters.

Superior Efficiency and Robust Construction

With efficiency ratings close to 98%, our transformers deliver greater energy savings and reliable performance. The double-winding design and high-quality materialscopper or aluminiumensure reduced losses and robust longevity, even in demanding industrial environments.

Comprehensive Service from Design to Delivery

As a leading manufacturer and supplier in India, we handle your orders end-to-end. From initial consultation to installation and after-sales support, our team ensures seamless integration of the transformer into your process, guaranteeing both safety and productivity.

We Are Mainly Deals In Uttarpardesh, Rajastaha, Uttaranchal, Punjab, Uttarakhand

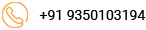

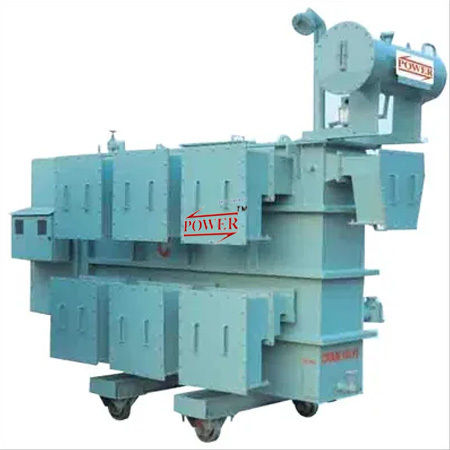

Electrical Furnace Transformers

Product Details:

- Rated Voltage Up to 33 kV

- Dimension (L*W*H) Depends on rating (Subject to design specification)

- Load Loss As per IS standard

- Voltage Booster Type Tap Changer Type (ON Load/ OFF Load)

- Coil Material Electrolytic Copper / Aluminium

- Low Voltage As per customer specification (typical: 400 V 1600 V)

- Capacity Customizable (as per requirement)

- Click to View more

X

Electrical Furnace Transformers Price And Quantity

Electrical Furnace Transformers Product Specifications

- 98% approx.

- Electrolytic Copper / Aluminium

- Three Phase

- Double Winding

- As per customer specification (typical: 400 V 1600 V)

- Copper / Aluminium

- Customizable (as per requirement)

- Up to 100 MVA

- Up to 33,000 V

- Up to 33 kV

- Depends on rating (Subject to design specification)

- As per IS standard

- 50 Hz

- Tap Changer Type (ON Load/ OFF Load)

- Varies with capacity, up to several tonnes

Product Description

From over a decade we have been consistently offering our clients Electrical Furnace Transformers. We fabricate the products with quality raw materials leveraging on most sophisticated design parameters. Our transformers find different applications in farms, sugar mills and steel plants for performing in all conditions. Renowned for its durability, easy installation and high performance features, this Electrical Furnace Transformers is available in different sizes and models as per the specification of our valuable clients.

Custom-Built for Your Furnace Needs

These electrical furnace transformers can be fully customized in terms of capacity, dimensions, low voltage requirements, and coil material. Whether for steel making, foundries, or specialty furnaces, our engineers design solutions that fit your exact operational parameters.

Superior Efficiency and Robust Construction

With efficiency ratings close to 98%, our transformers deliver greater energy savings and reliable performance. The double-winding design and high-quality materialscopper or aluminiumensure reduced losses and robust longevity, even in demanding industrial environments.

Comprehensive Service from Design to Delivery

As a leading manufacturer and supplier in India, we handle your orders end-to-end. From initial consultation to installation and after-sales support, our team ensures seamless integration of the transformer into your process, guaranteeing both safety and productivity.

FAQs of Electrical Furnace Transformers:

Q: How are electrical furnace transformers customized for specific applications?

A: We tailor transformers based on your required power scope (up to 100 MVA), voltage levels (up to 33,000 V on the high side and 4001600 V or more on the low side), and coil material preferences (copper, aluminium, or electrolytic copper/aluminium). Additionally, size and dimensions are adjusted to fit your infrastructure and process.Q: What is the process for installing these transformers in an industrial furnace setting?

A: Installation includes site assessment, transformer mounting as per IS standards, electrical connections, testing, and commissioning. Our expert engineers guide you through each step, ensuring the system is safely and efficiently integrated into your furnace operations.Q: When should tap changer type (ON Load/OFF Load) options be used?

A: ON Load Tap Changers are recommended when frequent voltage regulation is needed during operation, providing smooth adjustments without interrupting the power supply. OFF Load Tap Changers are suitable when voltage adjustments can be made during shutdowns or maintenance periods.Q: Where can these transformers be supplied and installed?

A: We manufacture and supply across India, catering especially to metal industries, foundries, and refineries. Our logistics and installation support ensure prompt delivery and setup at your preferred industrial site.Q: What are the key benefits of using copper or aluminium windings in these transformers?

A: Copper windings offer higher electrical conductivity and efficiency with reduced losses, making them ideal for heavy-duty, high-power applications. Aluminium windings provide a cost-effective alternative while maintaining good performance, especially in systems where weight reduction is critical.Q: How does the transformer ensure high energy efficiency?

A: Our transformers achieve around 98% efficiency by using high-quality coil materials, adhering to IS-standards for low load loss, and employing advanced design practices that minimize energy losses even at demanding power levels.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Transformers' category

We Are Mainly Deals In Uttarpardesh, Rajastaha, Uttaranchal, Punjab, Uttarakhand

|

ARORA ELECTRICALS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry Send SMS

Send SMS